Sheet metal fabrication is a process that shapes flat metal sheets into useful parts or products. This process helps create items for many industries, such as automotive, construction, and electronics. The main goal of sheet metal fabrication is to turn raw metal sheets into finished pieces with specific shapes and sizes. Workers use different tools and machines to cut, bend, and join the metal. Modern factories often use CNC Sheet Metal Fabrication Solutions to improve speed and accuracy.

The process of sheet metal fabrication usually follows these steps:

Generate blueprints

Finalize drawings

Fabricate the metal

Finish the product

Each step ensures the final product meets the required design and quality standards. Sheet metal fabrication allows companies to make strong, lightweight, and custom parts quickly.

Note: Sheet metal fabrication supports both small and large production runs. This makes it a flexible choice for many projects.

Sheet metal comes in many forms. The most common types include flat, embossed, and perforated sheets. Flat sheets are smooth and even. Embossed sheets have raised or sunken designs. Perforated sheets contain holes or patterns. Each form serves a different purpose in sheet metal fabrication.

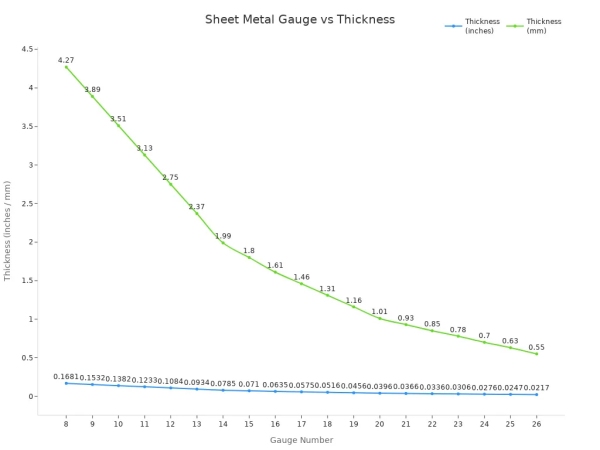

The thickness of sheet metal is important. It affects the strength and flexibility of the final product. The table below shows common sheet metal gauges and their thickness in inches and millimeters:

|

Gauge |

Thickness (inches) |

Thickness (mm) |

|---|---|---|

|

8 |

0.1681 |

4.27 |

|

10 |

0.1382 |

3.51 |

|

12 |

0.1084 |

2.75 |

|

14 |

0.0785 |

1.99 |

|

16 |

0.0635 |

1.61 |

|

18 |

0.0516 |

1.31 |

|

20 |

0.0396 |

1.01 |

|

22 |

0.0336 |

0.85 |

|

24 |

0.0276 |

0.70 |

|

26 |

0.0217 |

0.55 |

Sheet metal fabrication uses sheets that range from about 0.15 mm to 10 mm thick. Thinner sheets are easier to bend, while thicker sheets provide more strength. The choice depends on the needs of the project.

Sheet metal fabrication has many steps. Each step changes raw metal sheets into finished products. The process includes design and planning, cutting and punching, bending and forming, joining and assembly, and finishing. Every step uses special tools and methods to get the right result.

Design and planning is the first step. Engineers and designers make blueprints for each part. They use CAD software to build models. Some popular programs are Alibre, Onshape, FreeCAD, and Fusion 360. These tools help people design parts that are easy to make.

During this stage, designers think about important things:

Leave space for cuts and bends, including bend allowance.

Check metal thickness, especially if welding is needed.

Make sure parts fit the tools available.

Avoid designs that are too hard to keep costs low.

Add room for tolerance so parts fit well.

Good planning helps stop mistakes and saves material.

After planning, workers cut and punch the metal sheets. This step shapes the metal to the right size and form. There are several ways to cut and punch metal. The table below shows the main methods, what they do, and their benefits:

|

Technique |

Description |

Advantages |

|---|---|---|

|

CNC Punching |

Uses special tools and force to make holes and cutouts in metal. |

Fast production and flexible for repeating patterns. |

|

Laser Cutting |

Uses a strong beam to cut clean and precise shapes. |

Little waste and can cut complex patterns in many metals. |

|

Plasma Cutting |

Uses charged gas to melt thick metal quickly. |

Fast cutting, good for strong parts, but less exact than laser. |

|

Waterjet Cutting |

Uses high-pressure water with abrasives to cut without heat. |

No heat damage, can cut many thicknesses without changing tools. |

Laser cutting is very exact and fast. It can cut a 40 mm steel sheet much faster than old methods like bandsaws. But laser cutting machines cost more and may not work well with very thick metal. Old cutting methods cost less but may not make detailed shapes.

Next is bending and forming. Workers use machines to shape metal into angles, curves, or other forms. Bending is needed to make things like brackets, boxes, and frames. The table below lists common bending and forming methods:

|

Technique |

Description |

Applications |

|---|---|---|

|

V-Bending |

Uses a V-shaped die and punch to make angles in metal. |

General bending of sheet metal. |

|

Roll Bending |

Bends metal into curved shapes with rollers. |

Curving long sheet metal parts. |

|

Rotary Bending |

Bends metal at angles over 90 degrees with a rotating punch. |

Making large heavy-gauge parts. |

|

Edge Bending |

Bends only the edge of metal using a wiping die. |

Making edge parts for roofing. |

The forming method depends on a few things. Production volume matters. High-volume methods like stamping cost more at first but get cheaper for big jobs. Material type and part design also affect the choice. Picking the right method helps control costs and keeps quality high.

After shaping, workers join the metal parts together. Sheet metal fabrication uses different joining methods:

Welding: Uses heat and pressure to make strong, lasting bonds.

Riveting: Uses fasteners to join parts, so they can be taken apart.

Clinching: Bonds sheets without heat or extra stuff, using cold-forming.

Adhesive Bonding: Uses glue for good contact and protection from dirt.

Welding is the strongest and best for building strong things. Riveting is good when parts need to come apart or when joining different materials. Clinching and adhesive bonding make solid joints without heat.

|

Method |

Strength |

Application |

|---|---|---|

|

Welding |

85-100% base material strength, permanent bonds |

Building projects, big manufacturing jobs |

|

Riveting |

60-80% strength, predictable failure modes |

Planes, repairs, joints that come apart |

The joining method depends on how strong the bond needs to be and the project type.

Finishing is the last step. It makes products look better, last longer, and work well. Common finishing methods are:

Grinding

Polishing or buffing

Electropolishing

Painting

Powder coating

Blasting

Brushing

Powder coating and painting add color and protect from rust. Grinding and polishing make surfaces smooth. Electropolishing removes flaws and makes surfaces better. Blasting gives a matte look. These methods make products nicer and stronger.

Finishing makes products look good and protects them from rust, chemicals, and scratches. Good finishing adds value and helps products work well for their job.

Sheet metal fabrication uses all these steps to turn raw metal sheets into great finished products. Careful work at every step makes sure the results are strong, exact, and nice-looking.

Sheet metal fabrication uses different sheet metals. These metals help make strong and useful things. The most common sheets are steel, aluminum, copper, and brass. Each metal has special features for certain jobs. Most sheets are between 0.15 mm and 10 mm thick.

Steel sheets are used the most in sheet metal fabrication. They are strong and last a long time. Factories use mild steel, stainless steel, and galvanized steel. These sheets are good for car panels, appliances, and building supports. Steel sheets are usually 0.5 mm to 6 mm thick. Shops use sheets from 0.02 inches to 0.250 inches thick.

|

Steel Grade |

Yield Strength |

Hardness |

Ductility |

Weldability |

Machinability |

Corrosion Resistance |

|---|---|---|---|---|---|---|

|

S235 |

Low |

Soft |

High |

Easy |

Moderate |

Moderate |

|

S275 |

Moderate |

Moderate |

Moderate |

Easy |

Moderate |

Moderate |

|

S355 |

High |

High |

Moderate |

Moderate |

High |

Low |

Steel sheets make products strong and long-lasting. They bend and weld easily, which helps with many jobs.

Aluminum sheets are light and do not rust. These sheets are used in planes, cars, and buildings. Aluminum sheets often use alloys like 6061 and 5052. Their thickness is like other sheet metals. Aluminum sheets are easy to shape and recycle.

|

Advantage |

Description |

|---|---|

|

Lightweight |

Aluminum is much lighter than steel, so it is easy to use. |

|

Corrosion Resistant |

Aluminum has a layer that keeps it from rusting. |

|

Durability |

Aluminum sheets last a long time because they do not get damaged easily. |

|

Electrical Conductivity |

Aluminum carries electricity well, so it is used in electrical parts. |

|

Recyclable |

Aluminum can be recycled and still stays strong. |

Sheet metal fabrication also uses other metals. Copper sheets carry electricity well and are used in wires and pipes. Brass sheets look nice and are used for decorations and fittings. Stainless steel sheets do not rust and are used in kitchens and boats. Titanium sheets are strong and light, so they are used in planes and medical tools.

Other common sheet metals besides steel and aluminum:

Copper: Good for electrical and plumbing work.

Brass: Used for decorations and plumbing parts.

Stainless steel: Used in food, boats, and medical products.

Titanium: Used in planes and medical devices.

Picking the right sheet metal depends on the project. Each metal has special benefits for sheet metal fabrication.

Sheet metal fabrication uses many ways to change flat sheets. Each way helps make strong and exact parts for different jobs.

Cutting is the first thing workers do. Machines slice metal sheets into needed shapes and sizes. Some common cutting ways are laser cutting, plasma cutting, waterjet cutting, and CNC punching. These ways have many good points:

|

Advantage |

Description |

|---|---|

|

Lower Cost |

Saves money on tools and setup, good for small or big jobs. |

|

High Precision & Accuracy |

Makes detailed shapes with close measurements, gives neat cuts. |

|

Automation & CNC Control |

Works with machines, lowers mistakes, and makes parts the same. |

|

Speed & Efficiency |

Faster than old ways, can run all the time for more work. |

|

Versatility |

Works with many metals and thicknesses, fits many uses. |

Laser cutting is very fast and exact. Waterjet cutting is good for thick or heat-sensitive metal. CNC punching makes holes and patterns quickly.

Forming bends and shapes the cut metal. Workers use presses, dies, and rollers to mold the sheets. Some good forming ways are:

Hydroforming: Uses liquid pressure for tricky shapes.

Embossing: Makes textures on the metal.

Deep Drawing: Makes deep shapes.

Stamping: Cuts and shapes metal sheets neatly.

Electromagnetic Forming: Uses magnets to shape metal without touching it.

Hydroforming makes light parts with hard shapes. Stamping is used for car and electronic parts. Embossing adds designs for looks or grip.

Joining puts metal pieces together to make strong builds. Sheet metal fabrication uses different joining ways:

|

Joining Process |

Advantages |

Limitations |

|---|---|---|

|

Welding |

Makes a strong bond, good for thick metal |

Needs skill, can cost more |

|

Riveting |

Very strong, lasts long, stops shaking |

Needs to reach both sides of the metal |

|

Adhesives |

Sticks different metals, light weight |

Not good for high heat |

|

Mechanical Fasteners |

Easy to put together or take apart, useful |

Can add weight, might get loose |

Welding types like MIG, TIG, and spot welding make tough bonds. Riveting is good for parts that shake, like in planes. Adhesives and fasteners join different metals or help with repairs.

Surface finishing makes metal parts look better and last longer. Some popular finishing ways are powder coating, e-coating, zinc plating, Dacromet, and anodizing.

|

Surface Finish |

Corrosion Resistance |

Coating Thickness |

Abrasion Resistance |

|---|---|---|---|

|

Powder coating |

Stops rust if done right, but can rust if not |

35 to 200µm, thicker than paint |

Hard surface, does not scratch easily |

|

E-coating |

Blocks rust well |

12 to 30µm, even thickness |

Lasts a long time |

|

Zinc plating |

Protects metal by covering it |

5 to 25µm, good for small details |

Very tough |

|

Dacromet |

Blocks rust and chemicals |

5 to 7.6µm, can be painted |

Good against chemicals and scratches |

|

Anodizing |

Great for wet places |

0.5 to 150µm |

Hard and does not wear out fast |

Finishing keeps metal safe from rust, chemicals, and scratches. Powder coating and anodizing add color and make metal stronger. Zinc plating and Dacromet help stop rust in tough places.

Tip: Picking the best way in sheet metal fabrication helps products stay strong, look good, and last longer.

Many businesses use sheet metal fabrication to make important things. Farmers need custom metal parts for tractors and plows. The railroad industry uses strong metal pieces for trains and tracks. Aerospace companies need exact metal shapes for planes and satellites. Car makers use sheet metal fabrication for car bodies and engine parts. Pharmaceutical companies need clean metal for lab tools. Oil and gas companies use pipes, platforms, and tools made from sheet metal. Electronics and telecom companies use metal cases and connectors. Food service and HVAC companies need metal for kitchen appliances and cooling systems. Plumbing, medical, computer, military, storage, and construction fields also use sheet metal fabrication for many items.

In oil and gas, sheet metal fabrication makes pipes, platforms, and equipment for getting and cleaning oil.

Sheet metal fabrication makes many different products. Kitchen utensils like forks, knives, and spoons are made from metal sheets. Builders use custom spiral stairs and steel buildings. Hospitals need metal surgical tools and operating tables. Farmers use metal tractors and plows. Planes, trucks, and buses need metal parts for safety and strength. Bridges and sewer systems use metal parts too. Appliances like refrigerators and stoves are made with sheet metal fabrication.

Kitchen utensils

Spiral stairs

Steel buildings

Surgical tools

Tractors and plows

Planes, trucks, and buses

Bridges and sewer systems

Refrigerators and stoves

Sheet metal fabrication has many good points over other ways of making things. The table below shows the main benefits:

|

Benefit |

Description |

|---|---|

|

Cost-Effectiveness |

Saves material and lowers costs by using resources well. |

|

Precision and Consistency |

Makes parts accurate and the same with special machines and CAD. |

|

Fast Turnaround |

Gets products done faster and helps with quick testing. |

|

Material Versatility |

Works with many metals and non-metals for lots of uses. |

|

Environmental Friendliness |

Helps the planet by using less energy and waste, and supports recycling. |

|

Customization and Design Flexibility |

Lets people make detailed designs and change them quickly for different needs. |

Sheet metal fabrication helps many industries by making strong, exact, and custom parts. As technology advances, more opportunities appear. Many companies now choose Precision Sheet Metal Parts Manufacturing to improve efficiency and gain competitive advantages.

Businesses should think about what their project needs. They should talk to skilled fabricators for help. This way, they can work well together and get the right parts for their job.

Leave A Message

Scan to Wechat/Whatsapp :