|

Step |

Description |

Impact on Quality |

|---|---|---|

|

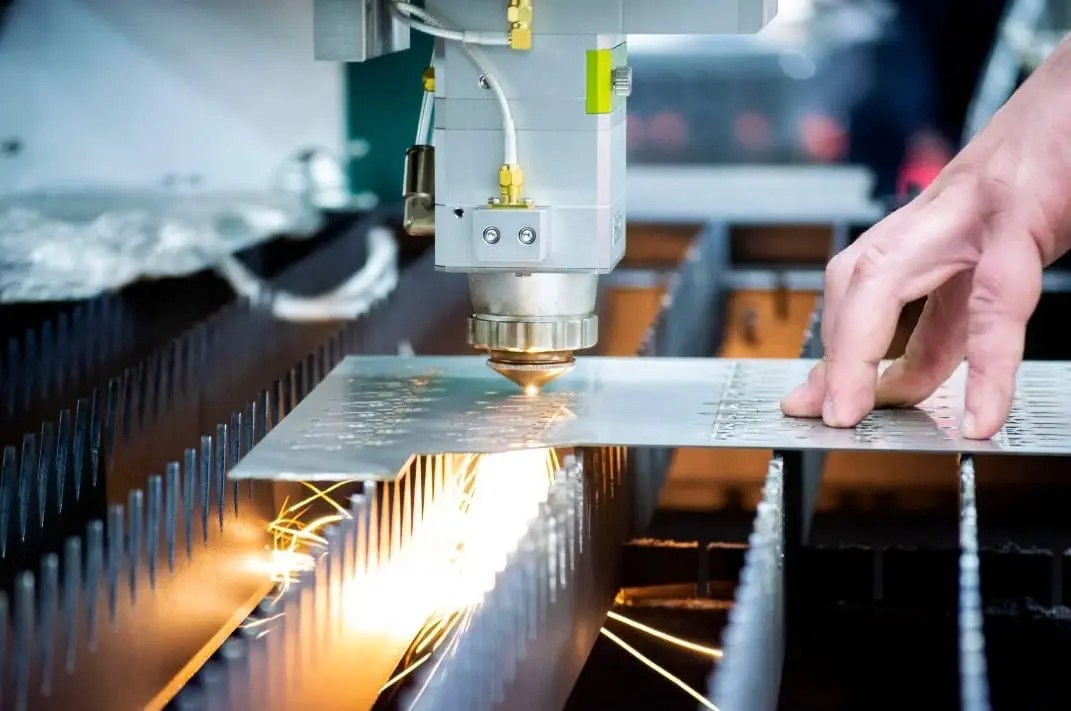

Cutting |

Uses careful methods like laser and water-jet cutting. |

Makes sure parts are exact and less metal is wasted. |

|

Bending |

Uses tools like CNC bending for exact angles. |

Needed for building complicated shapes. |

|

Assembling |

Uses welding, riveting, or glue. |

Changes how strong and good the final product is. |

Many businesses use the fabrication process to make metal parts that are strong and work well.

Know why each step in sheet metal fabrication matters. Cutting, bending, and assembling help make parts strong and exact.

Plan well when you design. Careful planning saves time and stops errors. This helps the product fit what the customer wants.

Pick the best materials for your project. Think about strength, weight, and cost. This helps your project work well and last long.

Use the right cutting methods for your needs. Techniques like shearing and laser cutting have different good points. They can be fast or very exact.

Use quality checks at every step. Check often to find mistakes early. This makes sure the final product is very good.

Every custom sheet metal fabrication project starts with an idea. Engineers and designers talk about what the product should do. They also think about how big and what shape it should be. Good planning helps teams avoid mistakes. It also saves time. If teams skip planning, they might have problems later.

The design phase has a few important steps. The table below shows how each step builds on the one before:

|

Stage |

Description |

|---|---|

|

Blueprint Creation |

Engineers make blueprints for the design. |

|

Rough Drawing |

Designers draw rough sketches to show their ideas. |

|

Finalized Drawings |

Teams finish detailed drawings to help with the custom sheet metal fabrication process. |

Careful planning is the base for the rest of the work. It helps teams pick the best materials and ways to build. This step also makes sure the final product is what the customer wants.

Technical drawings are very important in custom sheet metal fabrication. These drawings show all the details of the part. They include sizes, materials, and finishes. Clear drawings help teams be more accurate and waste less.

The table below explains how different parts of technical drawings help the process:

|

Key Element |

Influence on Fabrication Process |

|---|---|

|

Dimensions |

Makes sure parts are cut to the right size, so there is less waste. |

|

Tolerances |

Helps parts fit together well, making assembly better. |

|

Materials |

Tells teams what metal to use, which changes strength and cost. |

|

Finishes |

Decides how the surface looks and works. |

|

Processes |

Shows what methods to use, like bending and welding, for good results. |

Without good technical drawings, teams might have to guess. This can waste materials, cost more money, and slow down the project. Custom sheet metal fabrication needs accuracy at every step. When teams use clear drawings, they can make many types of sheet metal fabrication parts and feel sure about their work.

Engineers pick metals with care for the sheet metal manufacturing process. Steel is the most used metal. It makes up about 93% of all sheet metal manufacturing. Aluminum is becoming more popular each year. Many companies use it for parts that need to be light. Other metals like copper, brass, and titanium are also important. Each metal has special features that help in the sheet metal manufacturing process.

Steel: 93% market share

Aluminum: Fastest-growing segment

Copper, brass, titanium: Used for special applications

Steel is strong and lasts a long time. Aluminum is lighter and good for products that should not weigh much. Copper and brass do not rust easily and carry electricity well. Titanium is strong but does not weigh much. The sheet metal manufacturing process uses these metals to fit many different jobs.

Teams think about many things when picking metals for the sheet metal manufacturing process. They check how the metal will work in the finished product. If the part will be outside or get wet, it needs to resist rust. Strength and flexibility are important for how the part will be used. Teams also look at cost and weight. Some projects need metals that are easy to put together or easy to find.

Tip: Picking the best metal can save money and make products last longer.

The main things to think about are:

Corrosion resistance requirements

Mechanical properties

Cost constraints

Weight constraints

Assembly process

Availability of material

Engineers match these needs to each project. The sheet metal manufacturing process follows these rules to make strong and safe parts. Experts look at every choice before they decide. They know that picking the right metal helps the product work better and last longer.

Cutting is the first big step in making sheet metal parts. Workers use different ways to cut and shape metal sheets. The cutting method changes how fast, cheap, and good the product is. Safety is very important during cutting. Teams must follow rules to keep people and machines safe.

Blank-cutting is an early step in making sheet metal parts. Workers use machines to cut flat sheets into blanks. Blanks are pieces with special shapes and sizes. Shearing is a common way to do blank-cutting. This method uses force to cut straight lines fast. Shearing is good for making lots of simple shapes.

Blanking takes away extra metal and leaves the part you want. This way is good for making many of the same piece. But blanking makes waste, so teams need to plan to save money. The quality of the blanked piece matters for later steps. Good die design and smart material choices help lower waste and make better parts.

Tip: Planning well during blank-cutting can save metal and money.

Here is a table that compares two blank-cutting methods:

|

Feature |

Shearing |

Laser Cutting |

|---|---|---|

|

Process |

Mechanical (fracture) |

Thermal (melting/vaporization) |

|

Speed |

High (straight cuts) |

Variable (material, complexity) |

|

Precision |

Lower |

Higher |

|

Cost |

Lower |

Higher |

Shearing is quick and cheap for easy cuts. Laser cutting is more exact and works for hard shapes, but costs more.

Punching is another main step in making sheet metal parts. Workers use punches and dies to make holes or shapes in metal sheets. This way is fast and works well for making many parts. Punching works with many metals and can make parts that fit well.

Punching has good and bad sides. It is cheap for big batches and makes parts fast. But punching can bend the metal and change its shape. Setting up the tools takes time and money. Punching is not as good for thick metals or very detailed shapes.

|

Advantages |

Limitations |

|---|---|

|

Makes holes for less money |

Can bend or change the metal |

|

Fast and works well |

Tools need time and money to set up |

|

Works with many metal types |

Not as good for thick metals |

|

Cheap for big jobs |

Hard for very detailed shapes |

|

Makes parts that fit well |

High cost to start |

|

Fast production |

Can bend or change the metal |

Teams must think about speed, price, and quality when picking punching for sheet metal work.

New cutting tools have changed how people make metal parts. Laser cutting uses strong light to melt or burn metal. This way is very exact and works best for thin or medium sheets. Plasma cutting uses electric arcs to cut thick metals fast, but it is not as exact as laser cutting. Waterjet cutting uses water with sand or grit under high pressure. This way does not make heat, so the metal stays the same.

Here is a table that compares advanced cutting methods:

|

Feature |

Plasma Cutting |

Laser Cutting |

Waterjet Cutting |

|---|---|---|---|

|

Precision |

±0.02″ |

±0.002″ |

±0.001″ |

|

Speed on thick materials |

Fast |

Slow or not possible |

Moderate |

|

Heat impact |

Significant |

Moderate |

None |

|

Material versatility |

Conductive metals only |

Metals and some non-metals |

Almost all materials |

Laser cutting is best for thin sheets and is very exact. Plasma cutting is good for thick metals and is fast. Waterjet cutting is the most exact and works with almost any material, but it is slower.

Note: Teams must wear safety gear like gloves, tight clothes, and use machine guards when cutting. Fire extinguishers and first aid kits should be close by. Workers should use hoists and lift things the right way to stay safe.

Cutting is a key part of making sheet metal parts. Picking the right way helps make parts exact, saves metal, and keeps costs low. Teams must choose the best way for each job to get strong and good parts.

Bending turns flat metal into shapes we need. Workers use machines to bend metal at the right angle. Press brakes, folding machines, and roll benders are used a lot. Each machine bends metal in its own way. The tool picked depends on the part’s size and angle.

The bending process must control angle and thickness. Many things can change how close the part is to the plan. These things are the metal type, bend radius, and worker skill. Teams check tolerances so parts fit together well. The table below shows what changes bending tolerances:

|

Tolerance Type |

Factors Influencing Tolerance |

Material Examples |

|---|---|---|

|

Angular Tolerances |

Ductility, bend radius, tooling precision, multiple bends, operator skill |

N/A |

|

Thickness Tolerances |

Material type (hot-rolled vs cold-rolled), rolling process, stacked assemblies, surface finish |

Hot-rolled, Cold-rolled steel |

|

Flatness Tolerances |

Material variations, fabrication techniques, size and shape of parts, improvement methods |

Cold-rolled steel exhibits better flatness |

Tip: Teams should check the bend angle and thickness after each step. This helps keep the work going the right way.

Some jobs need more than just simple bends. Workers use special tools and machines to make curves and channels. Making these shapes takes more time and skill. Harder shapes mean longer setup and machine time.

Complex shapes take longer to set up and cost more.

Special tools and longer machine use raise the price for each part.

More programming and skilled workers are needed for hard shapes.

Making complex shapes can make the product stronger and better. But teams must plan for higher costs and longer times. Good planning helps teams handle these problems and keeps the work moving.

Note: Teams should think about the project’s money and time when making complex shapes.

Sheet metal fabrication uses different ways to join parts. These methods help make products strong and safe. The way parts are put together changes how well they work.

Welding is the most used way to join metal parts. Workers use heat, and sometimes pressure, to melt and join pieces. This makes a strong joint that does not break easily. Welding is important for jobs where safety is very important, like in planes and the military. Machines can do welding by themselves to make things faster and better. Teams pick welding when they want parts to stay together forever and look smooth. Welding keeps the metal strong and does not change it much with heat. Many metals can be welded, so it works for lots of projects. Welding makes things last a long time and look nice. That is why many companies use welding for frames, boxes, and cabinets.

Welding is the best way to make strong and lasting joints in metal work.

Riveting is good when teams need to join different materials or work in small spaces. Rivets come in many types, like solid, semi-tubular, and blind rivets. Each type is used for a special job. Riveting is helpful if the product might need to come apart or be fixed later. It does not use heat, so the metal stays the same. Riveting is slower than welding and can leave bumps that do not look nice. Teams use riveting in things like bridges, ships, and products people buy, where fixing is important.

|

Aspect |

Welding |

Riveting |

|---|---|---|

|

Strength |

Makes a stronger and more lasting joint |

Joints are weaker than welding |

|

Durability |

Very strong, good for hard frames |

Not as strong, good for taking apart |

|

Aesthetics |

Smooth finish, looks good |

Rivets can stick out and look bad |

|

Applications |

Used in planes, defense, and cabinets |

Used in products, bridges, and ships |

|

Efficiency |

Faster and easier, can use machines |

Slower, needs drilling and rivets |

Adhesive bonding uses glue to stick metal parts together. This way is best for thin sheets and parts that do not need to be super strong. Teams use glue when welding or riveting will not work. Glue makes the surface smooth and helps stop rust. Teams use adhesive bonding in electronics, car panels, and light parts. Glue does not make the part heavier and keeps it looking nice.

Teams should pick the joining method that fits the product’s needs to get the best results in sheet metal work.

Surface treatments help protect sheet metal from rust and damage. They also make metal look and feel better. Engineers use different ways to help metal last longer and work well. Some common surface treatments are:

Protective finishes like clear and yellow chromate, zinc coatings, and anodizing.

Chrome plating uses hard and black chrome for stronger protection.

Powder coating adds a tough layer that stops corrosion.

Anodizing makes the natural oxide layer stronger.

Wet paint is a cheap way to stop rust.

Galvanizing forms a strong bond with the metal.

Each treatment helps make parts safer and tougher. Teams pick the best method for each product and where it will be used.

Painting and coating give sheet metal another layer of protection. These finishes keep water and chemicals away from metal. They also help parts look nicer and last longer.

Coatings and finishes keep metal safe from things like water and chemicals. If metal does not have these layers, it can rust, get weak, or break. These coatings help parts last longer, even in tough places.

Finishes can also help parts work better. A smooth coating can make moving parts slide easier. Some coatings help electricity flow or stop scratches, depending on what is needed.

When teams add coatings or treatments, they make a shield that keeps metal safe from water, chemicals, and scratches.

Metal coatings make parts last longer and stay strong. They help parts handle lots of use and rubbing.

Teams use painting and coating to help products stay strong and look good for a long time.

Deburring and smoothing take away sharp edges and rough spots from sheet metal parts. This step makes products safer and helps them fit together better. Engineers use different ways to finish metal:

Cryogenic deburring uses very cold temperatures to make burrs easy to break off.

Magnetic deburring polishes edges without touching the metal.

Electrochemical deburring uses electricity for small, delicate parts.

Robotic deburring uses machines to do the job the same way every time.

Manual deburring uses hand tools for small jobs.

Mechanical deburring uses machines for big batches.

Thermal deburring uses small blasts to remove burrs.

Deburring helps products in many ways:

Parts work better when burrs are gone.

Smooth surfaces look nicer to buyers.

No sharp edges means fewer injuries.

Deburring is important for safety and how well parts work. When teams finish parts the right way, products work as planned and do not hurt anyone.

Quality control is very important in making sheet metal parts. Teams use different ways to check each step. They want to make sure every product is made well. This careful checking helps stop mistakes. It also keeps the work moving without problems.

Workers use many ways to check for mistakes in metal work. First, they look at the raw materials. They check papers, test how strong the metal is, and make sure it is right for the job. While making the parts, teams check sizes and test how things work. These checks help find problems early. Before sending out parts, teams do a final check. They make sure every part is good and meets the rules.

|

Inspection Method |

Description |

|---|---|

|

Raw Material Inspection |

Checks if materials are right by looking, testing, and reading papers. |

|

In-Process Inspection |

Finds mistakes during work by measuring and testing. |

|

Final Inspection |

Tests all parts before shipping to make sure they are good. |

Teams also check their tools and machines. This helps them measure things the right way. Some tests do not hurt the parts but still find problems on the surface. All these steps help teams make sure every part is made right.

Companies follow strict steps to make sure parts meet the rules. They pick workers who know what they are doing. Good machines and skilled workers help make parts that are just right. Companies check for special certificates like ISO 9001 to show they care about quality. They also follow rules for cutting, bending, and finishing.

Following the rules helps companies make products that customers can trust.

The steps for meeting the rules are:

Checking if workers have the right skills.

Using good machines for careful work.

Looking at certificates and following the rules.

Making sure quality is checked at every step.

By doing these things, companies make sure their work is always good. This helps them make strong and exact parts for many different jobs.

Sheet metal fabrication has some problems that can hurt quality and speed. Teams need to know these problems and use good fixes to keep things working well.

Material deformation can make cracks, spring-back, and dents. These problems make parts weaker and less safe. Workers notice deformation when metal does not stay in shape after bending or forming. Teams can stop these problems by doing a few things. They set the right process for each job. They pick molds and materials that fit the design. They use better machines to cut down on mistakes. They also teach workers to handle metal carefully. Good planning helps stop deformation and keeps parts strong.

Precision problems can make parts not line up or fit right. These problems happen when small errors add up during bending or when the wrong metal is used. Cracks and breaks at bends can happen if the bend is too sharp or the metal is not bendy enough. Teams can fix these problems in a few ways. They use CAD tools and check quality to keep parts lined up. They talk about the design with workers before starting. They pick metals that bend well. They use bigger bends to stop cracks. The table below shows what causes precision problems and how to fix them:

|

Problem |

Solution |

|---|---|

|

Tolerance stacking |

CAD tools, quality control |

|

Wrong alloy selection |

Proper material choice |

|

Cracks at bends |

Larger bend radius, ductile alloy |

Taking care of tools is important for making good parts. Old or dull tools can make dents, rough edges, and bad cuts. These problems cost more money and slow down work. Teams should check tools often for damage. They should change broken or dull tools fast. They also watch how tools work during jobs. Keeping tools in good shape helps the process go faster and makes better parts.

Tip: Teams can save money by making work easier and choosing skilled manufacturers.

Sheet metal fabrication is used in many industries. This process turns metal into products people use every day.

Car companies need sheet metal fabrication for many car parts. They use it to make body panels, frames, and other pieces. Aluminum is used a lot because it is light. Lighter cars use less gas and make less pollution. Factories use new machines and robots to make parts faster and better.

Some big changes in car metal work are:

More aluminum is used to make cars lighter

Harder shapes help cars be safer and look better

New ways to shape metal are used for electric cars

The market will grow from $133.29 billion in 2024 to $155.05 billion by 2029

Companies want strong supply chains and new safety features

These changes show that metal fabrication is very important for making cars today.

Builders use sheet metal fabrication to make buildings strong and last longer. Metal beams, panels, and supports help keep buildings safe. Some buildings use metal for almost everything. The process lets builders make special sheets and parts for each job.

Some things made with metal in building are:

Roofing and siding

Gutters and downspouts

HVAC ductwork

Architectural panels

Steel framing parts

Builders pick metal because it is strong and looks good. Metal parts also keep buildings safe from weather and last for years.

Electronics companies use sheet metal fabrication for many reasons. This process makes parts that fit well and last long.

The table below shows why metal work is important in electronics:

|

Benefit |

Description |

|---|---|

|

Precision |

Makes accurate parts for electronic devices |

|

Durability |

Keeps products working for a long time |

|

Customization |

Allows special designs for each project |

|

Thermal Management |

Helps control heat in devices |

|

Lightweight and Compact |

Makes small and light parts for modern gadgets |

|

Aesthetic Finishes |

Adds coatings that look good and stop rust |

Sheet metal fabrication helps electronics companies make products that are safe, strong, and look nice.

Sheet metal fabrication has many steps to make strong and exact products. Each step helps make the product better in its own way.

|

Step |

Contribution to Quality |

|---|---|

|

Working with Blueprints |

Makes sure the plans fit what engineers want. |

|

Finalizing Drawings |

Checks how much force the part can handle. |

|

Metal Fabrication |

Shapes the metal to the right size. |

|

Product Finishing |

Gets the product ready for people to use. |

Knowing about each step helps workers pick good materials. It also helps them cut metal the best way and put parts together the right way. This makes work faster, saves money, and makes products work better. People who want to learn more can find easy guides and videos about new ways and design ideas.

Leave A Message

Scan to Wechat/Whatsapp :